How Commercial Stainless Steel Sinks Contribute to LEED Certification

In the world of green building, LEED (Leadership in Energy and Environmental Design) certification is the gold standard for sustainability. But here’s a secret: commercial stainless steel sinks are a quiet hero in earning LEED points. They’re not just durable fixtures—they check key boxes for water efficiency, eco-friendly materials, and healthy indoor spaces. Below, we break down how these sinks power LEED success, with simple visuals to make the benefits clear.

Understanding LEED Certification and Its Relevance to Commercial Sinks

LEED certification is a globally recognized standard that evaluates the sustainability of building projects across multiple categories, including water efficiency, material selection, indoor environmental quality, and innovation. Each project aims to maximize its LEED points by adopting eco-friendly materials and practices.

Commercial stainless steel sinks shine in 3 key LEED categories:

--Materials & Resources (MR): Recyclable, long-lasting materials

--Water Efficiency (WE): Water-saving features

--Indoor Environmental Quality (EQ): Non-toxic, easy-to-clean surfaces

The Sustainable Advantages of Commercial Stainless Steel Sinks

1. Durability and Longevity Reduce Environmental Impact

Stainless steel is renowned for its exceptional durability and resistance to corrosion, staining, and impact. These qualities ensure that the sinks maintain their integrity over extended periods, significantly reducing the need for replacements. This durability minimizes waste generation and conserves resources, aligning with LEED’s emphasis on material lifespan and waste reduction.

2. Recyclability and Eco-Friendly Material Composition

One of stainless steel’s most compelling sustainability features is its high recyclability rate—up to 85% of stainless steel is recycled content. At the end of their lifespan, commercial stainless steel sinks can be fully recycled into new products, reducing the demand for virgin materials and lowering the environmental footprint associated with mining and manufacturing.

3. Non-Toxic and Low-Emission Material

Unlike some plastics or coated fixtures, stainless steel does not emit volatile organic compounds (VOCs) or other toxic substances that can compromise indoor air quality. This characteristic contributes to healthier indoor environments, a core consideration for LEED’s Indoor Environmental Quality (EQ) credits.

4. Resistance to Bacterial Growth and Ease of Maintenance

Stainless steel’s non-porous surface resists bacterial colonization, making it ideal for commercial kitchens, laboratories, and healthcare facilities. Its ease of cleaning reduces the need for harsh chemical disinfectants, further supporting indoor air quality and environmental safety.

How Commercial Stainless Steel Sinks Contribute to LEED Credits

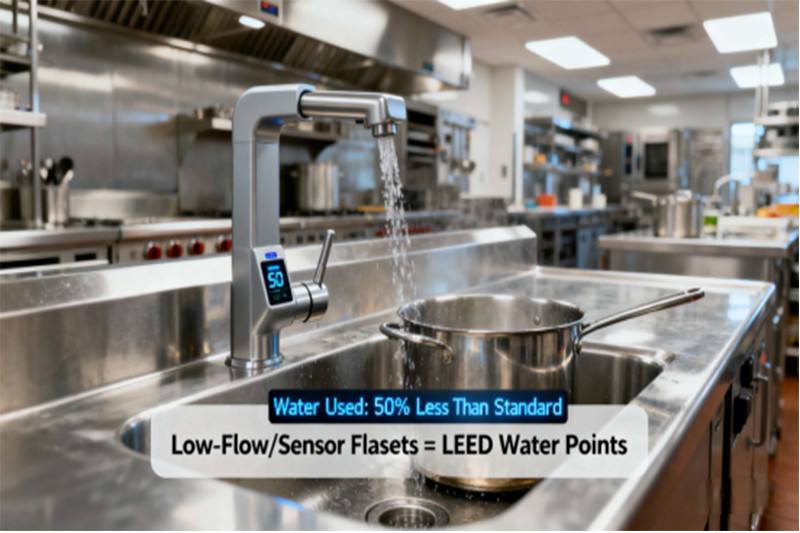

1. Water Efficiency (WE) and LEED Points

Water conservation is a fundamental LEED criterion, with points awarded for reducing water use through efficient fixtures. Many commercial stainless steel sinks incorporate features such as low-flow faucets and sensor-activated valves, which significantly reduce water consumption.

-Water-saving faucets can cut water usage by up to 30-50%, directly earning LEED points.

-Flow restrictors and automatic shut-offs optimize water use, especially in high-traffic areas like kitchens and restrooms.

2. Material and Resource Use (MR) Credits

Material selection is crucial in LEED certification. Stainless steel sinks contribute to Material and Resources (MR) credits through:

-Recycled Content: As mentioned, high recycled content enhances points toward LEED certification.

-Durability: Long-lasting fixtures reduce replacement frequency.

-Local Sourcing: Sinks manufactured locally qualify for points related to regional materials, reducing transportation emissions.

3. Indoor Environmental Quality (EQ) Benefits

Choosing stainless steel sinks minimizes VOC emissions and chemical off-gassing, ensuring healthier indoor air quality. Additionally, their non-porous surface inhibits mold growth, contributing to occupant health and comfort.

4. Innovation and Design (ID) Credits

Innovative LEED strategies involve integrating sustainable materials and practices. Installing energy-efficient, water-saving stainless steel sinks with sensor technology demonstrates a commitment to innovation, potentially earning additional points.

Design Considerations for LEED-Optimized Commercial Stainless Steel Sinks

Material Composition and Certification

Select EPA-approved or LEED-compliant stainless steel products with high recycled content and environmentally friendly manufacturing processes. Look for certifications like Greenguard or LEED Pilot Credits related to material transparency.

Water-Saving Technologies

Prioritize sinks with sensor faucets and flow restrictors to maximize water conservation. These features not only support LEED points but also reduce utility costs over the lifespan of the building.

Installation and Placement

Proper placement of sinks ensures optimal water and energy efficiency. For example, sensor-activated faucets should be installed at ergonomic heights to encourage use and reduce waste.

Maintenance and Longevity

Design for ease of cleaning and maintenance. Regular upkeep extends the lifespan of stainless steel fixtures, further supporting LEED’s waste reduction goals.

Case Studies: LEED-Certified Projects Using Commercial Stainless Steel Sinks

Green Office Complex in California

This project integrated sensor-operated stainless steel sinks in all restrooms and kitchens, earning LEED Gold certification. The sinks’ high recycled content and water-saving features contributed directly to multiple LEED credits, showcasing the eco-friendly impact of strategic material choices.

Healthcare Facility in New York

The facility utilized antimicrobial stainless steel sinks with low-flow faucets, improving infection control and water efficiency. The project achieved LEED Platinum, emphasizing the importance of sustainable fixtures in health-sensitive environments.

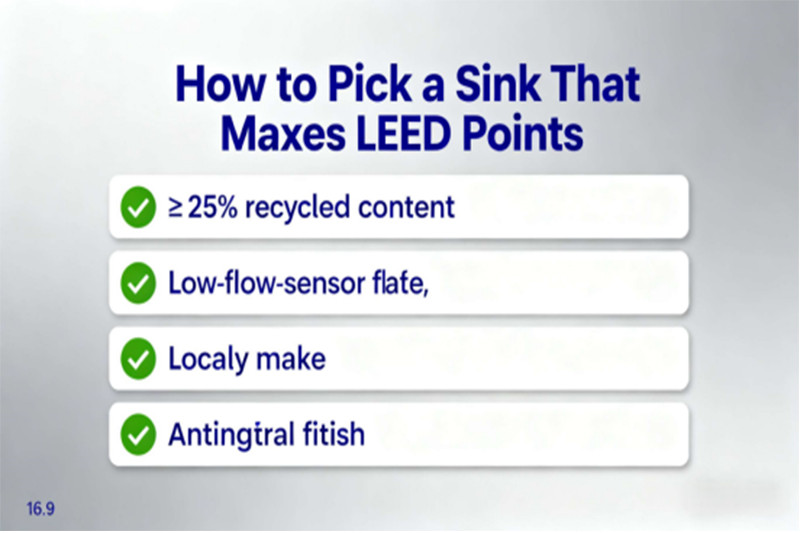

Best Practices for Implementing Stainless Steel Sinks to Maximize LEED Benefits

| Practice | Description | LEED Category Impact |

Use high recycled content stainless steel | Incorporate sinks with ≥ 25% recycled content | Material and Resources (MR) |

Install water-efficient fixtures | Use sensor faucets and flow restrictors | Water Efficiency (WE) |

| Source locally manufactured sinks | Reduce transportation emissions | Regional Materials (MR) |

| Opt for antimicrobial finishes | Enhance indoor environmental quality | Indoor Environmental Quality (EQ) |

| Ensure durable, low-maintenance designs | Minimize replacement and waste | Materials and Resources (MR) |

Conclusion: Elevating Sustainability with Commercial Stainless Steel Sinks

Incorporating commercial stainless steel sinks into building design is a strategic move toward achieving LEED certification and fostering sustainable, healthy environments. Their robust durability, high recyclability, and water-saving features make them indispensable components of eco-conscious construction.

By thoughtfully selecting and installing stainless steel fixtures aligned with LEED criteria, architects, developers, and facility managers can substantially contribute to green building goals, reduce environmental impact, and promote occupant well-being. The investment in high-quality, sustainable sinks is not only a step toward certification but also a commitment to long-term environmental stewardship and cost-effective building operations.

Maximize Your LEED Certification Potential with Samsink

As a trusted stainless steel sink manufacturer for over 30 years, Samsink combines sustainability, innovation, and global expertise to support your green building projects. Headquartered in Bangkok, Thailand, with advanced production bases in Asia, Samsink delivers high-quality, custom-engineered stainless steel sinks that meet rigorous international standards—including ISO 9001, NSF/ANSI 51, and cUPC—ensuring compliance and performance for LEED-eligible applications.

Using premium SUS304 and SUS316 stainless steel, our products are fully recyclable, non-toxic, and built for exceptional longevity—key factors in earning LEED points across Materials & Resources, Water Efficiency, and Indoor Environmental Quality categories. With rapid customization (OEM/ODM), fast delivery from finished inventory, and over 500 sink molds available, Samsink empowers developers, contractors, and designers to implement sustainable solutions without compromising on design or timeline.

Partner with Samsink—where “Just Sinks That Work” meets environmental responsibility—and turn your sustainability vision into reality.

Get in touch today to learn how we can help your project achieve LEED success.

Ready to elevate your project? Contact the Samsink team today for expert guidance on LEED-aligned sinks and tailored solutions that drive sustainability and performance. Visit https://www.samsink.com/contact-us.htm or email us to get started.