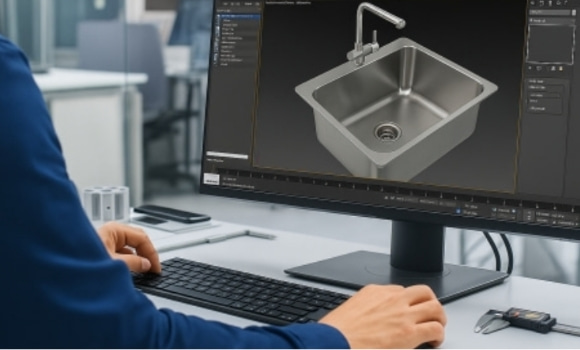

Samsink Stainless Steel Sinks Customization Service

ODM&OEM Stainless Steel Sinks

One-Stop B2B Solutions

Provider

With three decades of expertise in stainless steel manufacturing, we provide high-quality stainless steel utility sinks, commercial sinks, and industrial sinks for commercial kitchens, laundry rooms, garages, and industrial facilities worldwide. With OEM/ODM support and 15-day fast delivery, we help you seize market opportunities.

Custom Hot-Selling Stainless Steel Sinks

| Number | Product Image | Model No. | Product Descriptions | Dimensions | Available Stock (pcs) | MOQ (pcs) | Remarks | Action |

|---|---|---|---|---|---|---|---|---|

| 1 |  | SM-DRD3322-10 | Stainless Steel Kitchen Sink | 30*22*10 | 10,000 | 100 | Finished Sinks 10,000 pcs SS Coils 10,000 kgs | Get Quote |

| 2 |  | OX-URD23189B-US | Single Commercial & Kitchen Sink | 23*18*9 | 2,000 | 100 | Finished Sinks 2,000 pcs | Get Quote |

| 3 |  | SB6045 | Stainless Steel Single Bowl Sink | 600*450*130/180mm | 3,000 | 100 | Finished Sinks 3,000 pcs, Ready to ship | Get Quote |

| 4 |  | DD403 | Stainless Steel Utility Sinks | 750*400*130mm | 5,000 | 100 | Finished Sinks 5,000 pcs | Get Quote |

| 5 |  | DD403M | Single Bowl Sink with Single Drain Board | 750*400*130mm | 5,000 | 100 | Finished Sinks 5,000 pcs and Stainless Steel Coils 20,000 kgs | Get Quote |

| 6 |  | DD402N | Stainless Steel Garden Sinks | 960*430*145mm | 6,000 | 100 | Finished Sinks 6,000 pcs | Get Quote |

| 7 |  | DD405 | Single Bowl Sink with Single Drain Board | 1000*500*140/160mm | 3,000 | 50 | Finished 3,000 pcs | Get Quote |

| 8 |  | DD8643 | Single Bowl Sink with Single Drain Board | 860*430*152mm | 6,000 | 100 | Stainless Steel Plates 6,000 kgs | Get Quote |

| 9 |  | DD1250 | Single Bowl Sink with Single Drain Board | 1200*500*150mm | 3,000 | 50 | Finished Sinks 3,000 pcs | Get Quote |

| 10 |  | UD820X | Stainless Steel Undermount Double Bowl Sink | 32*18"*9" | 10,000 | 50 | Finished 5,000 pcs Semi-finished 5,000 pcs | Get Quote |

| 11 |  | UD820 | Undermount Double Bowl Sink | 32*20-3/4""*9" | 1,000 | 50 | Finished 1,000 pcs | Get Quote |

| 12 |  | US591 | Stainless Steel Undermount Single Bowl Sink | 23"*18"*9" | 5,500 | 100 | Finished 2,500 pcs Semi-finished 3,000 pcs Stainless Steel Plate Stock 3,000 pcs | Get Quote |

| 13 |  | OX-1550-01 | Stainless Steel Work Sink | 26"*18"*9" | 1,500 | 100 | Semi-finished Sinks 1,500 pcs | Get Quote |

| 14 |  | GA-7070-01 | Commercial kitchen SS Sinks | 30"*18"*9" | 5,800 | 50 | Finished Sinks 4,800 pcs Semi-finished Sinks 1,000 pcs Stainless Steel Coils 3,000 kgs | Get Quote |

| 15 |  | US826 | Stainless Steel Undermount Sink | 32"*18"*9" | 1,500 | 50 | Semi-finished Sinks 1500 pcs | Get Quote |

| 16 |  | RV2515 | Undermount Double Bowl RV Sink | 25"*15"*5-1/5" | 5,000 | 50 | Finished Sinks 5,000 pcs | Get Quote |

| 17 |  | OS106C-6 | Stainless Steel Topmount Single Bowl Sink | 25"*22"*6" | 3,000 | 100 | Finished 2,000 pcs Semi-finished 1,000 pcs SS Coils 8,000 kgs | Get Quote |

| 18 |  | YP211C-6 | Stainless Steel Topmount Single Bowl Sink | 15"*15"*6" | 500 | 100 | Semi-finished Sinks 500 pcs SS Coils 6,000 kgs | Get Quote |

| 19 |  | SM-7070-01 | Stainless Steel Medical Sinks | 17"*25"*6" | 5,000 | 100 | SS Coils 5000 kgs | Get Quote |

| 20 |  | T603C-6 | kitchen Topmount Double Bowl Sink | 33"*22"*6" | 10,000 | 50 | SS Coils 10,000 kgs | Get Quote |

| 21 |  | T603C-8 | Topmount Double Bowl Sink | 33"*22"*8" | 5,500 | 50 | Finished 3,500 pcs Semi-finished 2,000 pcs SS Coils 10,000 kgs | Get Quote |

| 22 |  | LAB-4040-01 | Stainless Steel Laboratory Sinks | 17"*15-1/2"*13.5" | 1,300 | 50 | Finished 300 pcs Semi-finished 1,000 pcs | Get Quote |

| 23 |  | SM-C1715-2 | Industrial Utility Sink | 17"*15-1/2"*13.5" | 600 | 50 | Finished 300 pcs Semi-finished 300 pcs | Get Quote |

| 24 |  | SM-C1715-2 | Stainless Steel Restaurant Sinks | Customizable | 600 | 50 | Finished 300 pcs Semi-finished 300 pcs | Get Quote |

| 25 |  | PGT-8080-01 | Stainless Steel Pet Grooming Tubs | Customizable | 600 | 50 | Finished 300 pcs Semi-finished 300 pcs | Get Quote |

Last updated: Sep., 10th, 2025

Finished Sinks: Ready to ship; Semi-finished sinks: Requires surface treatment, such as mirror finish, glossy finish, sanding, and brushing;

For more customization options, please contact us. We will provide you with one-stop high-quality service.

Samsink Stainless Steel Sink Customization Process

Custom Mold + High-Speed Production for Stretched Sinks

Requirement Analysis & Mold Design

Design molds based on client specs (CAD modeling or sample), mold production after confirmation (2 weeks).

Material Preparation

Select suitable stainless steel type to ensure successful forming, apply protective film to prevent scratches.

Stretching/Stamping Forming

Use hydraulic presses to stretch sheets into sink shapes (one-piece or multi-step).

Trimming & Welding (if needed)

Edge finishing, welding multi-bowl sections for smoothness.

Surface Treatment

Cleaning, polishing, nano-coating (black/gold/silver), or PVD plating.

Quality Inspection & Delivery

Batch testing, packaging, and shipping for OEM bulk orders, delivery in 5-8 weeks.

Mold-Free Customization for Handmade Sinks & Commercial Sinks

Requirement Consultation & Design

Clients provide specs (e.g., size, material, bowl count, package requirement), and the team designs and confirms drawings.

Material Preparation

Select type 304/316 stainless steel sheets (0.8-3.0mm thick), precisely cut.

Hand Forming & Welding

Use manual welding and laser welding to assemble sink basins and drainboards, ensuring seamless joints.

Surface Treatment & Polishing

Brushing, mirror finish, nano coating (gold/silver/black) or PVD coating to enhance corrosion resistance.

Quality Inspection & Testing

Durability and leak tests, compliant with ISO standards.

Packaging & Delivery

Bulk packaging with global logistics support, delivery in 4-6 weeks.

Samsink Customization Capabilities & Services

Flexible Size/Material

Supports custom mm, high-durability 316 stainless steel.

Design Innovation

3D complex shapes, OEM optimization.

Surface/Features

Nano-coating (nano black, nano gold, nano silver), anti-slip integration for commercial durability.

Custom Stainless Steel Sink Service Advantages

Supply Chain Integration: Prototyping (5-7 days), bulk production (100+ units efficient line); global logistics support.

Cost Control: Tiered pricing, long-term contract discounts.

Quality & Compliance: Third-party certification, lifespan testing (20+ years durability).

Quick Quotation For Stainless Steel Sinks

Competitive Pricing

Free Design & Technical Support

Stock Check & Fast Delivery Options

Drawings, Samples & Product Specifications

Customization Solutions

Contact Us for More Information

- Quick Quotation

- Mobile Phone

Why Choose Samsink Stainless Steel Sinks Manufacturer?

| Procurement Needs | Samsink Solutions | Benefits |

|---|---|---|

| Bulk Efficiency | Supports 300+ units/batch, two production bases | Shortens delivery time, reduces unit cost |

| OEM/ODM Flexibility | Branding, design modifications | Fast market response, enhanced competitiveness |

| Quality Assurance | ISO9001/ASTM A240/NSF/uCPC certification | Reduces returns, ensures compliance |

| Supply Chain Support | One-stop from design to logistics | Simplifies procurement, saves time |

| Long-Term Partnership | Framework agreements, exclusive discounts | Stable supply, cost control |

FAQs about Stainless Steel Sink Customization

- What Is the Production Lead Time for Custom and Standard Sinks?Standard Orders (with existing molds): 4–6 weeksCustom Mold Development + Sample: 4–8 weeksHandmade Custom Sinks (small batch): 7–10 days per batchSamsink supports flexible delivery schedules and provides real-time order tracking for transparency.

- How Long Does It Take to Develop a Custom Mold for Stainless Steel Sinks?For new mold development, the typical timeline is:Design & Engineering: 1–2 weeksMold Manufacturing: 3–5 weeksSample Production & Approval: 1–2 weeksTotal: 4–8 weeksOnce approved, production batches can be completed in 1–2 days, with flexible delivery options (4–6 weeks for standard orders).

- Can Samsink Produce Custom-Shaped Stainless Steel Sinks Without Molds?Yes. Samsink specializes in handmade, mold-free manufacturing for non-standard or complex sink designs, such as irregular shapes, integrated countertops, or commercial kitchen equipment.Process: CAD design → laser cutting → CNC bending → laser/argon arc welding → hand grinding → surface treatmentMinimum Order Quantity (MOQ): 5 piecesLead Time: 7–10 days per batchAdvantages: Unlimited design flexibility, high-end finish, ideal for boutique hotels, labs, and medical facilitiesWe also offer sample services (cost deductible from order) and full IP protection.

Flexible Collaboration, Faster Time-to-Market

- Mobile Phone

- *Title

- *Content