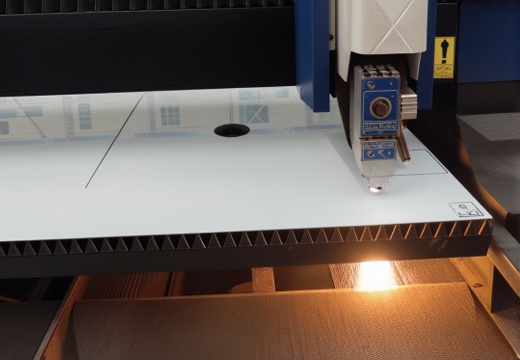

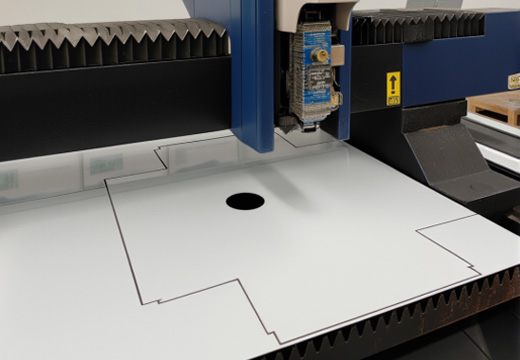

Raw Material Preparation

Select high-quality stainless steel sheets (thickness 0.8-1.2mm, grade 304/316) and inspect for surface defects and chemical composition.

Equipment:

Laser cutting machine, material testing instrument.

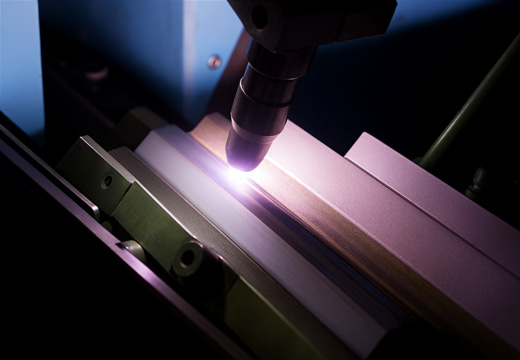

Key Parameter:

Plate hardness HRB 80-90 to ensure resistance to cracking during stretching.

Quality Control:

Third-party material certification verification, 100% sampling rate.